Probably the most important tool of our job was SCISSOR’s, this could make or break you, and the MOST! scariest sound you will ever have is a LOUD!! KRINKLE!!!!! KRACKLE!!!! (film/paper tearing or wrap-around). We worked mostly in a dark-room, clean-room environment with lab coats, or bunny suits, gloves and masks.

These were some of the machines we used:

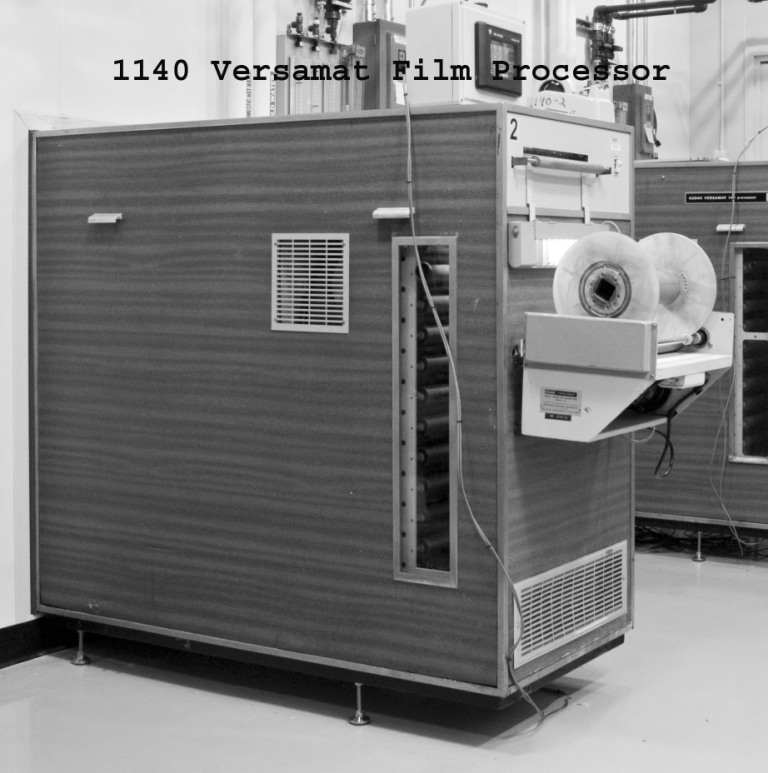

KODAK VERSAMAT Film Processor, Model 1140, is a heavy-duty, high-speed, self-threading roller transport processor. It is designed for rapid processing and drying of black-and-white aerial camera negative and duplicating roll films up to 9½ inches (240 mm) wide.

Ideal for high-volume productivity, the Model 1140 Processor produces top-quality, dust-free negatives at variable speeds from 5 to 40 feet (1.5 to 12.2 m) per minute. The process developer temperature can be adjusted over the range of 80-110°F (26.7 and 43.3°C).

Versatility: The Model 1140 can process and dry continuous lengths of aerial camera negative and duplicating roll films 70 mm to 11 inches (27.9 cm) wide at elevated developer temperatures. It also can handle non-aerial roll films and sheet films at normal processing temperature and machine speeds. (see picture)

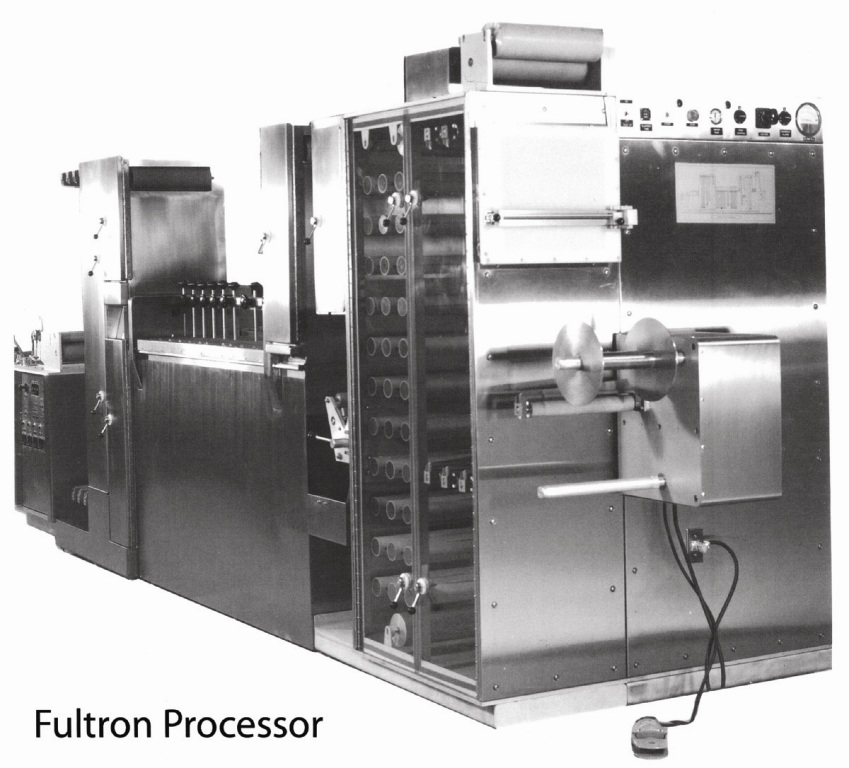

FULTRON Film Processor,

It is designed for rapid processing and drying of black-and-white aerial camera negative and duplicating roll films up to 9½ inches (240 mm) wide. Ideal for high-volume productivity, the Fultron Processor produces top-quality, dust-free negatives at variable speeds from 2 to 50 feet. This machine could be pre-threaded with a splicing table on the front, for continuous operations. This was an spray developer process.(see picture)

Niagara/Redondo Printer,

(548 RTG Photo Lab Niagara Printer, courtesy of Ulrich Seike)

The Niagara Printer is a drum-type continuous precision contact printer designed to produce high-quality film or paper reproductions from print master rolls. The printer handles processed film rolls in standard widths from 70 mm to 9.5 inches. Notable features include a six-speed transport system, self-centering easy load spindles, a raiseable lamp house, print master slewing capability, single-frame printing capability, a controlled variable light source for adjusting duplicate contrast, and a film cleaner. The Niagara Printer produces duplicate films in the following manner: print master film and raw stock (unexposed) duplicate films are unreeled from separate supply spools at the same rate. Print master and raw stock are brought together by a pressure roller on a printing drum and exposed to a high intensity light. The print master and exposed raw stock are then rewound on separate take-up spools. The print master film can then be returned to storage and the newly exposed film prepared for processing.

· NOTE: The term print master can refer to either processed negative or positive film.(see picture)

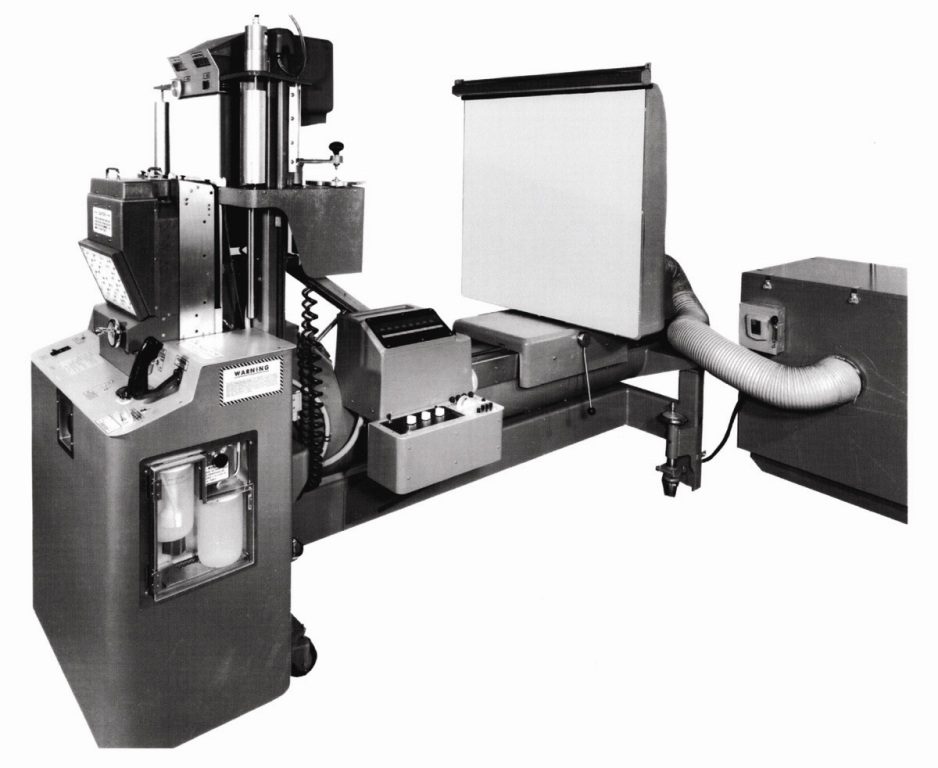

BPE- Beacon Precision Enlarger,

The BPE was used to make photographic enlargements from preselected areas of positive or negative, color or black and white films in standard widths of 70mm to 9.5 inches. A wide range of magnifications could be selected by the operator: 3x to 150X! with a combination of condensers and lens. The enlarger produced black and white prints on several types of photograph film and paper. (see picture)

OTHER Equipment USED:

COLOR Processors for E-6, EP-2 Paper prints.

· Enlargers for printing.

· Camera’s, NIKON -35mm, Bironica- 70mm.

· Various light tables.

(Photos and narrative courtesy of Ben Oakes)

(Courtesy of Ulrich Seike)